Test & Qualification Facilities

Our manufacturing units are equipped with testing and qualification facilities for various functional and prototype tests.

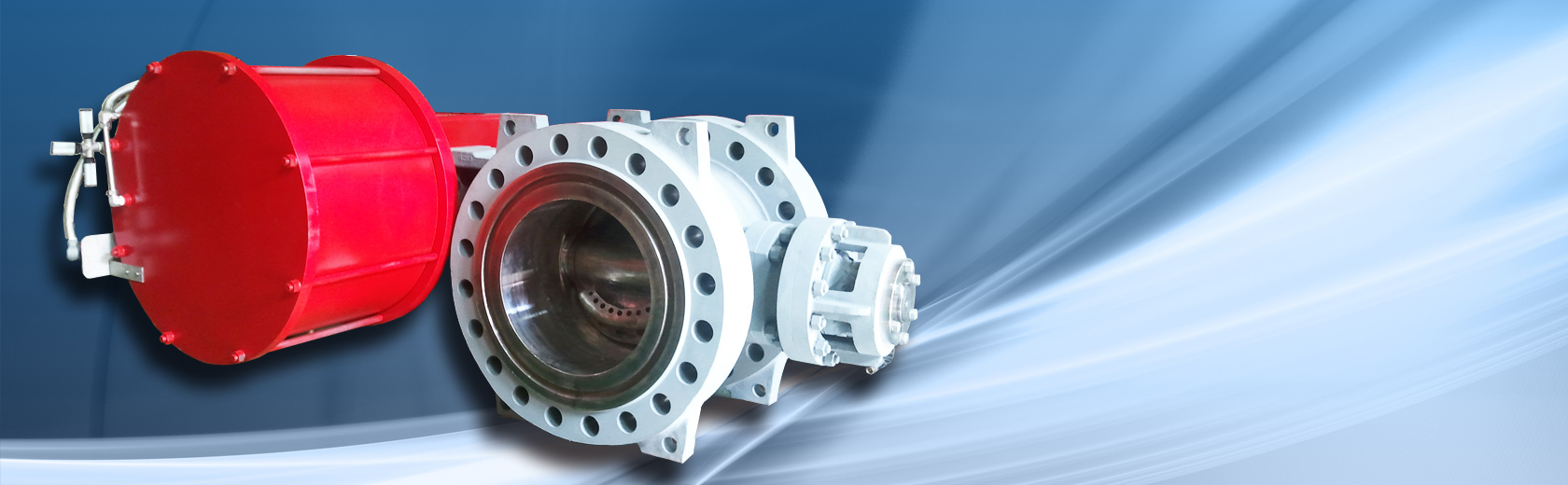

High Pressure Butterfly Valve

Pneumatic Control Butterfly valve Tested at 282bar.g

ANSI 1500LB 26″ / DHC-DS25M SERIES

BUTTERFLY VALVE

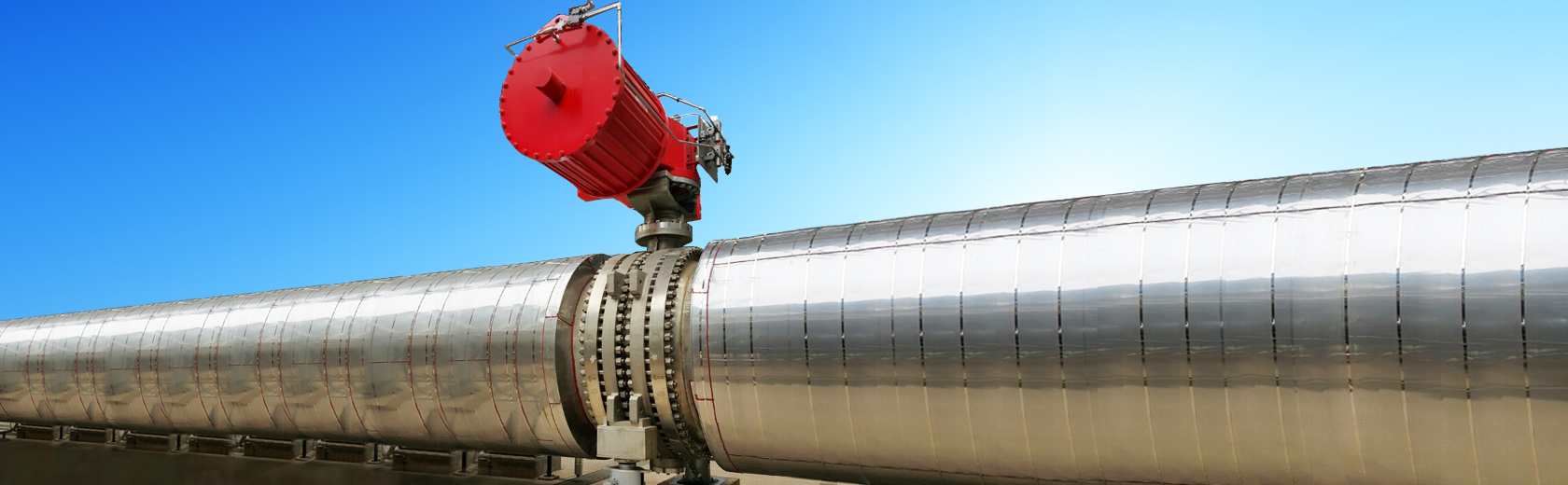

Triple Offset Butterfly Valve Buttwelding Type(60 Inch)

Pneumatic Quick Operation (3 Sec)

DHC-BT1M-WE Series

SPECIAL VALVE

Butterfly valve 78″

WORLD BEST D.H.C

Pneumatic Actuator Control Valve 1400A (Cavitation Free)

DHC-BD3B Series

SPECIAL VALVE

Aqua Seal Valve (Gas Shut Off)

DHC-AS Series

SPECIAL VALVE

Our manufacturing units are equipped with testing and qualification facilities for various functional and prototype tests.

NDT is carried out by ASNT level II qualified personnel :

Non-destructive testing methods are used to examine a valve.

They identify the cracks in the body, discontinuities in the material include porosity, wall thinning from corrosion and other sorts of disbands.

Radiographic tests are used for volumetric casting defects

Ultrasonic tests are used for forging defects

Magnetic particle test and liquid penetration tests are used for surface defects

Used to detect blow, scar, and blister on surface of casting -Magnetic particle test and liquid penetration test are used for surface casting defects.

Fugitive emission tests to evaluate the amount of fugitive emission leakage through the stem gland packing and shell joints.

DAEHAN CONTROL Co., Ltd.

Address : 39, Gadal 1-ro, Gangseo-gu, Busan, 46729, Republic of Korea

Tel : +82-51-974-1221 / Fax : +82-51-955-6041

e-mail : dhc@dhcv.co.kr